- flexible to handle a variety of parts

- easily moved from production line to production line

- easy for technicians to quickly check parts

THE SOLUTION

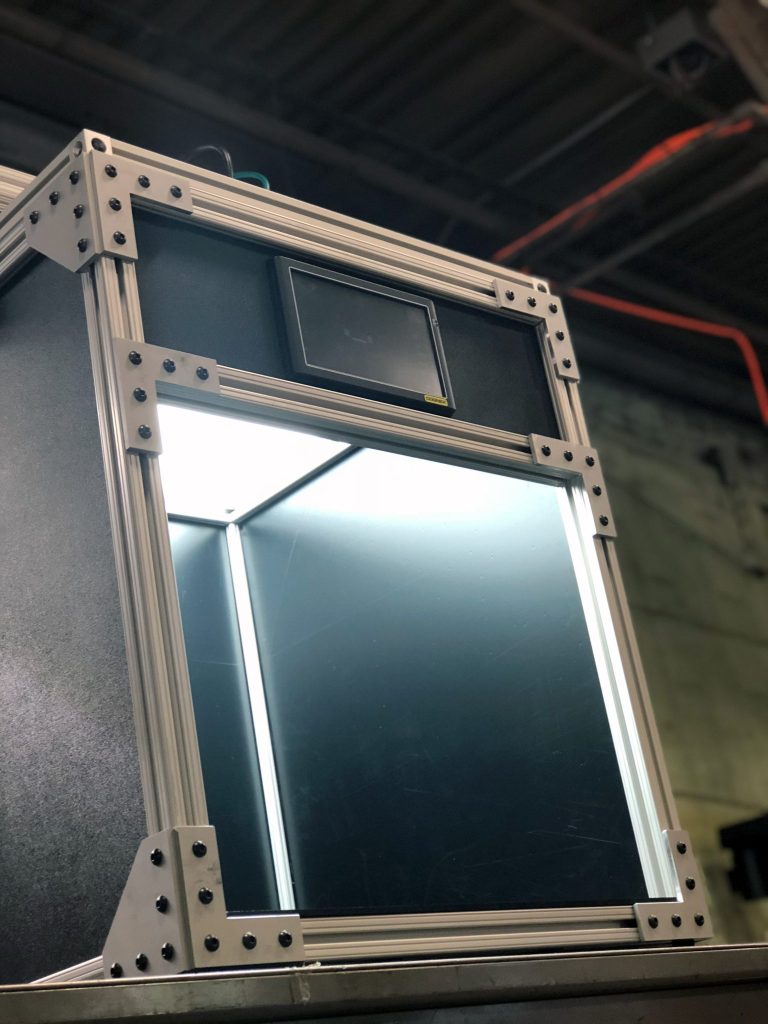

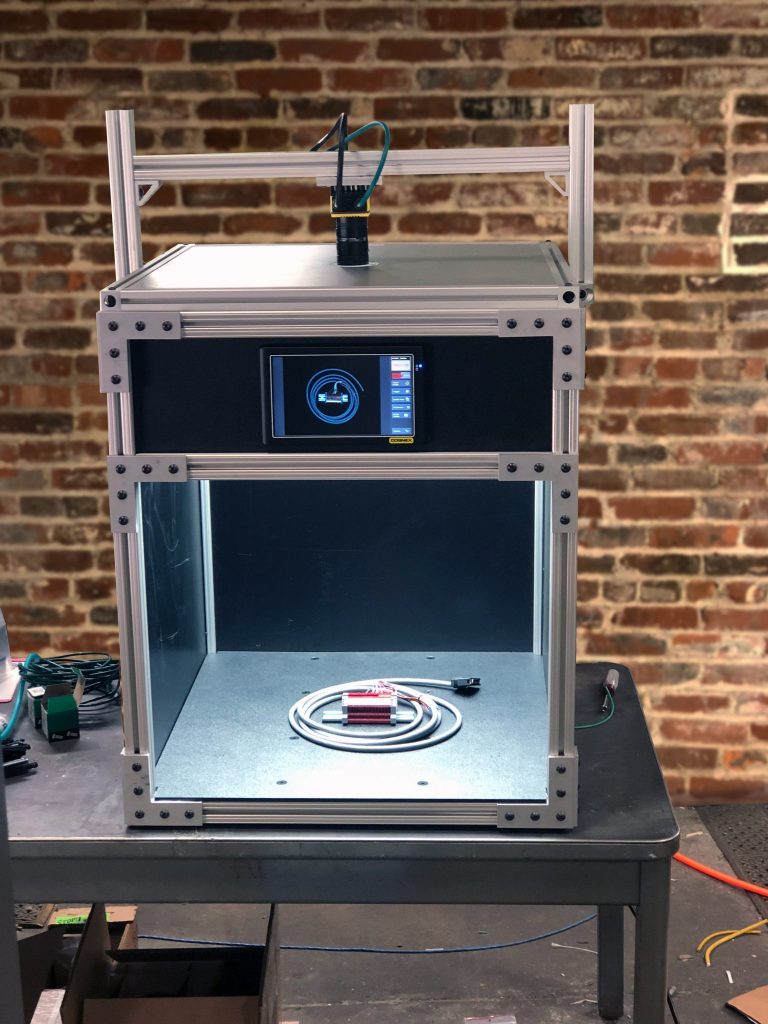

The Proud Company designed, built, programmed, and delivered an all-in one inspection station featuring a Cognex InSight high resolution color camera, an enclosure with shielding from ambient lighting, inspection-quality LED lighting, and a graphical buy gabapentin online interface to display images and inspection results, as well as switch between part recipes. The system only requires a standard 110VAC wall plug to operate, but also has I/O and network connections for programming and future expansion. The enclosure has built-in LED lighting and dark walls to shield ambient lighting, since the system will be relocated throughout various areas of the plant. The system can be easily lifted and moved, or placed on a mobile cart.

FAST DELIVERY AVAILABLE

Similar, custom systems are available with fast delivery: We can provide systems tailored to suit your specific application needs. Options include:

- Cameras: Low, mid, high, and super-high resolution, color and grayscale

- Lighting: Ring, dome, bar, backlight, or combinations based inspection needs

- Enclosure: Sized for optimal inspection results based on part size and camera resolution, optional portable stand

- Options: Network/Ethernet connections, discrete I/O, Serial, pushbuttons, tower lights

- Programming: Optional programming services available for “plug and play” solutions

To discuss your automated inspection needs, contact The Proud Company‘s Sales Engineers at 412.838.0230.

Recent Comments