WE HELP COMPANIES

AUTOMATE

Customer demands, and the technologies used to meet them, are constantly evolving. To keep up with evolving demand, automation is used to make things faster, smarter, more accurate, and more cost effective — allowing you to operate at your best, and giving you a competitive advantage.

Because each application and each customer is unique, we have adapted our business accordingly. Rather than dictating what our involvement should be, we let the customer choose how involved they want us to be. The vast majority of our work falls into one of these three categories:

- Component Only

- Our team helps select the right component(s) for the project, and we provide support when needed. Check out this list of our manufacturers.

- Components + Engineering Service

- After the right components are selected, our team of engineers assists the customer in some way to shorten the learning curve or to ensure a smooth installation. Typical engagements would include services like application assistance, programming and/or product training.

- Turnkey Systems

- For customers who don’t have the resources to complete projects on their own, our dynamic team has the capability to take your project from concept to installation and beyond.

For over 20 years, we’ve helped our customers with machine control, robotics, machine vision applications, data collection and reporting, and other automation challenges in manufacturing and other industrial settings. Leveraging our technological expertise we are ready to tackle your most challenging applications.

In order to compete tomorrow, manufacturers must strive to be faster, smarter and better today. We can help you get there.

AREAS OF EXPERTISE

MACHINE VISION

Using camera systems to measure, inspect and identify products or features for quality or traceability purposes

MOTION CONTROL

Electromechanical solutions to move things with a high level of precision and repeatability

INDUSTRIAL NETWORKING

Networking devices and machines together to collect and manage data that enables intelligent business decisions

ROBOTICS

A wide range of traditional 6 axis, SCARA, collaborative and mobile robots to automate any task

PROCESS CONTROL

Monitoring and controlling temperatures, speeds and flow rates from local or remote locations

SOFTWARE DEVELOPMENT

HMI/SCADA or custom software applications that provide a graphical interface for machine, plant or process data

CHECK OUT OUR PROJECTS PORTFOLIO

Portable Heat Treating Equipment

Created a fully networked PLC-based control system, along with both a local interface and a web-based GUI to allow for remote control over a very complex heat treating process

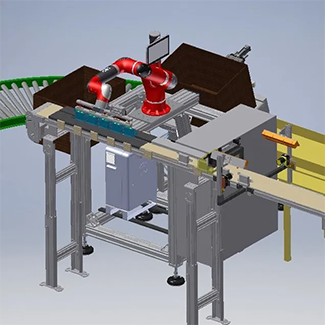

Packaging Cell For Injection Molding Company

Developed a COBOT-based system that fully automates the inspection, organization and packaging of 220 injection molded parts

Finished Goods Delivery With Mobile Robot

Created a fully networked PLC-based control system, along with both a local interface and a web-based GUI to allow for remote control over a very complex heat treating process

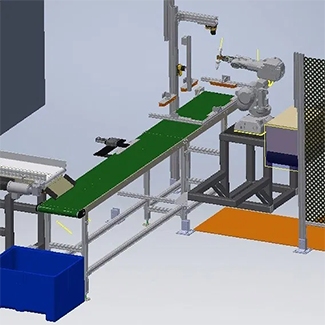

Robotic Line Loading

Automated the material handling of metal parts from a quench tank to a vision guided robot that would pick the part, present it to an inspection system and load the good parts onto a fixed conveyor every 5 seconds

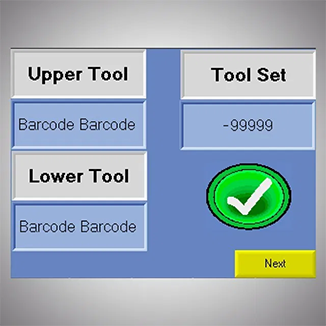

Closed System Part Traceability

Created an add-on system for an OEM machine to verify a correct part was placed in the correct part fixture, utilizing barcode readers to read 2D codes/part/fixture and a PLC/HMI to verify an acceptable combination and provide operator feedback

Barcode Readers For Medical OEM

An OEM in the medical industry had an application for a barcode reader that required a ~20″ depth of field and custom lighting due to the shiny material on which the barcode was printed