We teach robots. We give eyes to machines. We give our customers the ability to control and troubleshoot a remote site from the comfort of their home. We make machines and processes faster, smarter and better through the utilization of industrial automation technology.

Our team thinks outside the box and stays abreast of the latest technologies. Knowing how things are made, how things work and how to make them better is not just our job — it’s our passion.

We’re always looking for other talented, creative, passionate folks to join our team. Is that you? If so, let’s talk.

CHECK OUT OUR WORK

Portable Heat Treating Equipment

Created a fully networked PLC-based control system, along with both a local interface and a web-based GUI to allow for remote control over a very complex heat treating process

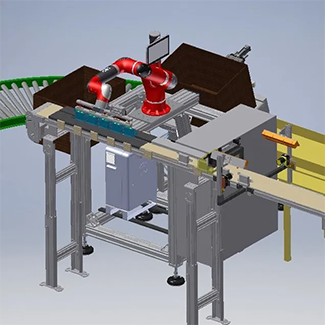

Packaging Cell For Injection Molding Company

Developed a COBOT-based system that fully automates the inspection, organization and packaging of 220 injection molded parts

Finished Goods Delivery With Mobile Robot

Created a fully networked PLC-based control system, along with both a local interface and a web-based GUI to allow for remote control over a very complex heat treating process

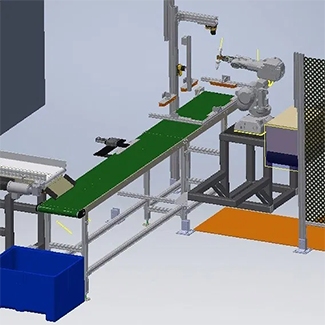

Robotic Line Loading

Automated the material handling of metal parts from a quench tank to a vision guided robot that would pick the part, present it to an inspection system, and load the good parts onto a fixed conveyor every 5 seconds

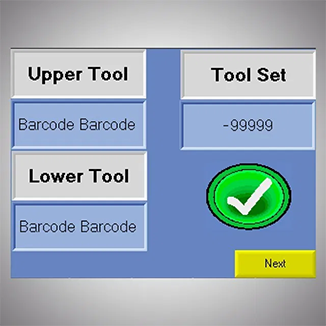

Closed System Part Traceability

Created an add-on system for an OEM machine to verify a correct part was placed in the correct part fixture, utilizing barcode readers to read 2D codes/part/fixture and a PLC/HMI to verify an acceptable combination and provide operator feedback

Barcode Readers For Medical OEM

An OEM in the medical industry had an application for a barcode reader that required a ~20″ depth of field and custom lighting due to the shiny material on which the barcode was printed