You’ve probably heard in the news and from others that automation is going to hurt the labor market. What you may not have heard is all of the ways that it can help.A study done by Manpower indicates that employers are expecting to increase their staff by 87% because of automation. Many of these roles will be complementary to the automated workforce.But, what are these new jobs that are being created? Will automating our old jobs help? We answer those questions in this post.Keep reading to learn about the advantages that automation brings and how it will help solve labor issues.

A History of Automation

Job loss through progress isn’t a new concept. It has happened throughout most of human history.Every time it happens, there is the talk of it destroying the workforce. Despite that, automation had eliminated a total of one job type when advances in technology were made in the past 60 years.Some jobs will lose demand, but they usually don’t disappear. Then you get the job creation that stems from the need for a new kind of workforce.You can see this trend in the past 25 years where a third of jobs created didn’t exist before.How Automation Will Create New Jobs

There are more things to look forward to than the automation of repetitive tasks when new automation tools are created. We can look forward to the development of new, complimentary jobs for these tools.How else do you expect to manage all your new tech?

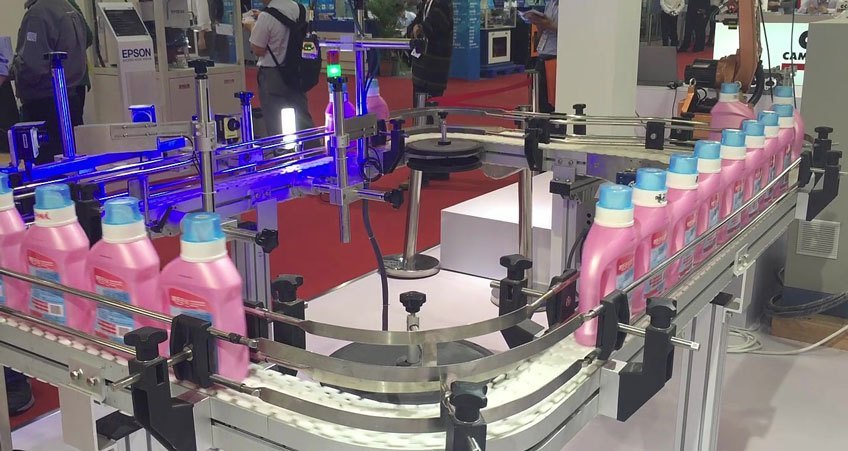

It’s called collaborative robotics. This advancement will lead to more workers working alongside these machines instead of being replaced by them.New advances in machine vision have led to safety advances that make this possible now. Robots will stop dangerous actions when they see any humans or obstacles that may get in the way.For example, Amazon employees manage robot workers to make sure everything at the warehouse runs smooth.Increase Worker Productivity

Will some jobs disappear because of automation? Sure, that’s a given.But, some workers will become even more productive at their job with new automation tools.For example, take the California finishing company that purchased a painting robot. Their new robot was able to increase worker productivity by a factor of four.Even better, they didn’t lose any workers to this. One of the workers who used to do the paint job also runs the robot now.And how about material transports?Gone are the days of workers shuffling back and forth to get what they need to work. An autonomous mobile robot can handle this for you while giving your employees more time to do what they are great at.Rising Worker Wages

A study done by Deloitte in the U.K. didn’t just find an increase in jobs. The study found that the average worker salary increased by $13,000 per year compared to the jobs that disappeared because of automation.Eliminating the need for manual works makes room for higher positions where people can contribute to the company on a higher level.And since these jobs may require a higher level skill, companies will pay for it. With automation increasing productivity and increasing profits, they can afford to pay their workers more.Eliminate Repetitive Jobs

How many people enjoy doing the same thing throughout the whole day? Probably not many.Moving people stuck in repetitive jobs into something more diverse and enjoyable will increase worker satisfaction.Many manual jobs aren’t mentally stimulating. This repetition leads to boredom in the workplace. Allowing your workers to challenge themselves mentally at the office could be just the kick they need to be a more active contributor.Reduce Simple Mistakes

Advances in machine vision don’t just help safety issues. It also reduces errors when working with parts.Machine vision is a technology that provides automatic imaging inspection that guides robotics. The market for vision technology is expected to grow to $33.3 billion in 2019, so you can expect this technology to get even better.By having this technology, you can develop automated robotic systems that can perform precise movements that can generally be only be accomplished by humans.But, humans make mistakes at times. Automation will solve this by making precise movements all of the time. With a human counterpart to make sure the machine keeps working correctly, you have a winning combination that will improve your bottom line.Get Rid of Dangerous Jobs

Worker safety is a big concern in the workplace. This concern is more true for the factory, warehouse, and construction jobs where workers need to handle dangerous equipment.When accidents happen, it costs you not only money but also productivity. On the worker side, how much of a morale hit do you see when workers see a fellow employee get hurt?With automation, safety becomes less of a concern. Machines don’t get hurt.Keep Jobs Local

With talks of a minimum wage increase, companies are looking to move production overseas to save money.With automation you can save those jobs by automating the jobs you would otherwise outsource.Automation not only allows you to keep a tighter control on quality but also allows you to bring in local talent to help manage things.Solving Labor Issues With Automation

As you’ve read, there is a lot to look forward to with automation. Labor issues are one of the main concerns with progress, but automation seems to be a positive force for the issue.From new jobs to increased productivity, the future looks bright for anyone willing to take on the challenges. And when you train your workers to take on these challenges, you are not only helping yourself but helping shape the workers of tomorrow.If you are a company looking to take the first step in automation, head over to see our capabilities to learn how we can help!

Recent Comments